- What is digital marking used for?

A unified digital marking system (track & trace) will allow the business to boost productivity, improve logistics processes, and increase market share and, eventually, revenue:

According to a study by the National Research University Higher School of Economics (April 2021), in 2020, 0.67 billion packages of antiseptics and disinfectants were sold in Russia, while the share of illegal (unobserved) turnover of such products amounted to 51%, an increase compared to 2018-19 (ten%);

— The business will be able to switch production to the Industry 4.0 and just-in-time principles. By tracking warehouse stocks, product movements and shipments online, businesses will be able to optimise their production planning, reduce stock surpluses, and improve turnaround times;

— The business will be able to ensure deep accounting at all stages of the production and logistics cycle. Today, many entrepreneurs do not have their own data on stock on hand and goods codes in warehouses and shops. Inventory accounting will optimise costs and increase efficiency;

— The business will switch to electronic document management. EDM will help radically reduce the volume of paper documents that Russian companies are still actively exchanging with one another, cut expenses, and increase labour productivity.

- What is digital marking used for?

A unified digital marking system (track & trace) will allow the business to boost productivity, improve logistics processes, and increase market share and, eventually, revenue:

According to a study by the National Research University Higher School of Economics (April 2021), in 2020, 0.67 billion packages of antiseptics and disinfectants were sold in Russia, while the share of illegal (unobserved) turnover of such products amounted to 51%, an increase compared to 2018-19 (ten%);

— The business will be able to switch production to the Industry 4.0 and just-in-time principles. By tracking warehouse stocks, product movements and shipments online, businesses will be able to optimise their production planning, reduce stock surpluses, and improve turnaround times;

— The business will be able to ensure deep accounting at all stages of the production and logistics cycle. Today, many entrepreneurs do not have their own data on stock on hand and goods codes in warehouses and shops. Inventory accounting will optimise costs and increase efficiency;

— The business will switch to electronic document management. EDM will help radically reduce the volume of paper documents that Russian companies are still actively exchanging with one another, cut expenses, and increase labour productivity.

- What is digital marking used for?

A unified digital marking system (track & trace) will allow the business to boost productivity, improve logistics processes, and increase market share and, eventually, revenue:

According to a study by the National Research University Higher School of Economics (April 2021), in 2020, 0.67 billion packages of antiseptics and disinfectants were sold in Russia, while the share of illegal (unobserved) turnover of such products amounted to 51%, an increase compared to 2018-19 (ten%);

— The business will be able to switch production to the Industry 4.0 and just-in-time principles. By tracking warehouse stocks, product movements and shipments online, businesses will be able to optimise their production planning, reduce stock surpluses, and improve turnaround times;

— The business will be able to ensure deep accounting at all stages of the production and logistics cycle. Today, many entrepreneurs do not have their own data on stock on hand and goods codes in warehouses and shops. Inventory accounting will optimise costs and increase efficiency;

— The business will switch to electronic document management. EDM will help radically reduce the volume of paper documents that Russian companies are still actively exchanging with one another, cut expenses, and increase labour productivity.

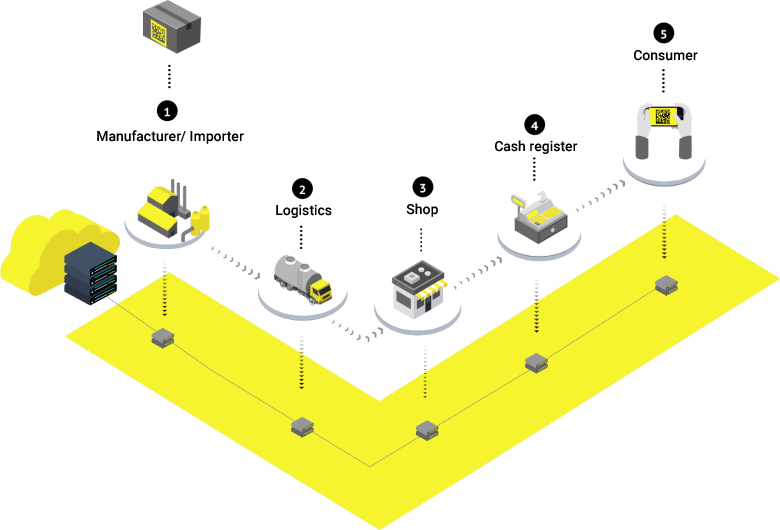

- What is the track & trace system based on?

December 2017 Russian President Vladimir Putin approved the government’s decision to create a national track & trace system by the year 2024. The project is being implemented as a public/private partnership without reliance on the federal budget. The government has appointed the Centre of Research in Perspective Technologies (CRPT) to operate the system.

The track & trace system is based on digital code technology using the Data Matrix standard, which stores data on each inventory item, as well as cryptographic protection, which makes it impossible to falsify the code. A unique code is applied to each inventory item during production or import (for specific groups of goods).

To ensure the traceability of the marked goods, electronic document management is used.

To monitor the disposal of marked goods, a system has been implemented to exchange information on the fact of the disposal of goods and, along with it, the goods code through fiscal data operators.

This approach ensures full traceability of goods from the production line (import) to the cash register and eliminates the possibility of introducing unmarked goods into circulation.

The use of the digital technology also makes it possible to expand social control mechanisms through the use of the Chestny ZNAK mobile application. It allows buyers to check the legality and specifications of goods and send complaints to regulatory authorities.

- What is the track & trace system based on?

December 2017 Russian President Vladimir Putin approved the government’s decision to create a national track & trace system by the year 2024. The project is being implemented as a public/private partnership without reliance on the federal budget. The government has appointed the Centre of Research in Perspective Technologies (CRPT) to operate the system.

The track & trace system is based on digital code technology using the Data Matrix standard, which stores data on each inventory item, as well as cryptographic protection, which makes it impossible to falsify the code. A unique code is applied to each inventory item during production or import (for specific groups of goods).

To ensure the traceability of the marked goods, electronic document management is used.

To monitor the disposal of marked goods, a system has been implemented to exchange information on the fact of the disposal of goods and, along with it, the goods code through fiscal data operators.

This approach ensures full traceability of goods from the production line (import) to the cash register and eliminates the possibility of introducing unmarked goods into circulation.

The use of the digital technology also makes it possible to expand social control mechanisms through the use of the Chestny ZNAK mobile application. It allows buyers to check the legality and specifications of goods and send complaints to regulatory authorities.

- What is the track & trace system based on?

December 2017 Russian President Vladimir Putin approved the government’s decision to create a national track & trace system by the year 2024. The project is being implemented as a public/private partnership without reliance on the federal budget. The government has appointed the Centre of Research in Perspective Technologies (CRPT) to operate the system.

The track & trace system is based on digital code technology using the Data Matrix standard, which stores data on each inventory item, as well as cryptographic protection, which makes it impossible to falsify the code. A unique code is applied to each inventory item during production or import (for specific groups of goods).

To ensure the traceability of the marked goods, electronic document management is used.

To monitor the disposal of marked goods, a system has been implemented to exchange information on the fact of the disposal of goods and, along with it, the goods code through fiscal data operators.

This approach ensures full traceability of goods from the production line (import) to the cash register and eliminates the possibility of introducing unmarked goods into circulation.

The use of the digital technology also makes it possible to expand social control mechanisms through the use of the Chestny ZNAK mobile application. It allows buyers to check the legality and specifications of goods and send complaints to regulatory authorities.

- What information is stored in the marking code?

1) GTIN goods code of 14 digits;

2) Individual serial number of 13 characters;

3) Verification code, which ensures verification of the originality of the marking code.

- What information is stored in the marking code?

1) GTIN goods code of 14 digits;

2) Individual serial number of 13 characters;

3) Verification code, which ensures verification of the originality of the marking code.

- What information is stored in the marking code?

1) GTIN goods code of 14 digits;

2) Individual serial number of 13 characters;

3) Verification code, which ensures verification of the originality of the marking code.

- How is the marking code applied to the packaging and what changes need to be made to the packaging design?

of a survey of production sites by system integrators together with representatives of the Operator and manufacturers.

In difficult cases, individual package form factors can be submitted for additional laboratory studies to determine how to apply a marking code of required quality to a specific form factor and to validate the quality of the application when reading.

- How is the marking code applied to the packaging and what changes need to be made to the packaging design?

of a survey of production sites by system integrators together with representatives of the Operator and manufacturers.

In difficult cases, individual package form factors can be submitted for additional laboratory studies to determine how to apply a marking code of required quality to a specific form factor and to validate the quality of the application when reading.

- How is the marking code applied to the packaging and what changes need to be made to the packaging design?

of a survey of production sites by system integrators together with representatives of the Operator and manufacturers.

In difficult cases, individual package form factors can be submitted for additional laboratory studies to determine how to apply a marking code of required quality to a specific form factor and to validate the quality of the application when reading.

- What changes will need to be made to the packaging to apply Data Matrix?

A small area of approximately 13×13 mm is required for applying the code on a label or lid. The exact application size and place can be determined after carrying out experimental work at the enterprise.

- What changes will need to be made to the packaging to apply Data Matrix?

A small area of approximately 13×13 mm is required for applying the code on a label or lid. The exact application size and place can be determined after carrying out experimental work at the enterprise.

- What changes will need to be made to the packaging to apply Data Matrix?

A small area of approximately 13×13 mm is required for applying the code on a label or lid. The exact application size and place can be determined after carrying out experimental work at the enterprise.

- What types of equipment need to be put on the line?

Label printer, applicators (in the case of labelling), machine vision — if marking in production. If printing marking codes on a label in a printing shop — machine vision only. In more detail, the composition of the equipment, its location, and integration into the line can be determined based on the results of a survey of the production site.

- What types of equipment need to be put on the line?

Label printer, applicators (in the case of labelling), machine vision — if marking in production. If printing marking codes on a label in a printing shop — machine vision only. In more detail, the composition of the equipment, its location, and integration into the line can be determined based on the results of a survey of the production site.

- What types of equipment need to be put on the line?

Label printer, applicators (in the case of labelling), machine vision — if marking in production. If printing marking codes on a label in a printing shop — machine vision only. In more detail, the composition of the equipment, its location, and integration into the line can be determined based on the results of a survey of the production site.

- Is it necessary to update the inventory accounting system for the release of marked products?

For small and micro enterprises, the User Account is available. If this option is inconvenient, then the existing inventory accounting system will need to be finalised/upgraded for integration with the User Account of the track & trace system. For medium and large enterprises, integration with inventory accounting and automated warehouse systems is recommended without fail in order to significantly simplify interaction with the track & trace system.

- Is it necessary to update the inventory accounting system for the release of marked products?

For small and micro enterprises, the User Account is available. If this option is inconvenient, then the existing inventory accounting system will need to be finalised/upgraded for integration with the User Account of the track & trace system. For medium and large enterprises, integration with inventory accounting and automated warehouse systems is recommended without fail in order to significantly simplify interaction with the track & trace system.

- Is it necessary to update the inventory accounting system for the release of marked products?

For small and micro enterprises, the User Account is available. If this option is inconvenient, then the existing inventory accounting system will need to be finalised/upgraded for integration with the User Account of the track & trace system. For medium and large enterprises, integration with inventory accounting and automated warehouse systems is recommended without fail in order to significantly simplify interaction with the track & trace system.

- If I am an importer, what should I do with the imported goods?

After the introduction of mandatory marking, unmarked goods will not be able to pass through customs of the Russian Federation. The application of the marking code on the imported goods must be carried out in production or in the customs warehouse.

- If I am an importer, what should I do with the imported goods?

After the introduction of mandatory marking, unmarked goods will not be able to pass through customs of the Russian Federation. The application of the marking code on the imported goods must be carried out in production or in the customs warehouse.

- If I am an importer, what should I do with the imported goods?

After the introduction of mandatory marking, unmarked goods will not be able to pass through customs of the Russian Federation. The application of the marking code on the imported goods must be carried out in production or in the customs warehouse.

- What must a retail point of sale have?

— Enhanced qualified electronic signature (issued in one of the certification centres accredited by the Russian Ministry of Digital Development, Communications and Mass Media);

— 2D barcode scanner for reading the Data Matrix code;

— Online checkout for retail sales (firmware update may be required);

— Document exchange configured using an electronic document management operator for the acceptance of goods to the warehouse;

— When working in the inventory accounting program, the turnover participant can integrate it with the User Account of the track & trace system.

- What must a retail point of sale have?

— Enhanced qualified electronic signature (issued in one of the certification centres accredited by the Russian Ministry of Digital Development, Communications and Mass Media);

— 2D barcode scanner for reading the Data Matrix code;

— Online checkout for retail sales (firmware update may be required);

— Document exchange configured using an electronic document management operator for the acceptance of goods to the warehouse;

— When working in the inventory accounting program, the turnover participant can integrate it with the User Account of the track & trace system.

- What must a retail point of sale have?

— Enhanced qualified electronic signature (issued in one of the certification centres accredited by the Russian Ministry of Digital Development, Communications and Mass Media);

— 2D barcode scanner for reading the Data Matrix code;

— Online checkout for retail sales (firmware update may be required);

— Document exchange configured using an electronic document management operator for the acceptance of goods to the warehouse;

— When working in the inventory accounting program, the turnover participant can integrate it with the User Account of the track & trace system.

- How much does a marking service cost?

The cost of the service for the traceability of marked goods (generation and provision of a marking code/storage of information on the transfer of a marking code between legal entities for one inventory item), approved by Decree of the Government of the Russian Federation No 577 dated 8 May 2019, shall be 50 kopecks excluding VAT fixed for 15 years.

- How much does a marking service cost?

The cost of the service for the traceability of marked goods (generation and provision of a marking code/storage of information on the transfer of a marking code between legal entities for one inventory item), approved by Decree of the Government of the Russian Federation No 577 dated 8 May 2019, shall be 50 kopecks excluding VAT fixed for 15 years.

- How much does a marking service cost?

The cost of the service for the traceability of marked goods (generation and provision of a marking code/storage of information on the transfer of a marking code between legal entities for one inventory item), approved by Decree of the Government of the Russian Federation No 577 dated 8 May 2019, shall be 50 kopecks excluding VAT fixed for 15 years.

- When must the marking code payment be made?

For the duration of the experiment, the emission of marking codes is free. Upon completion of the experiment, from the date of the start of mandatory digital marking, the debiting of funds will occur until the submission of information about the introduction of goods into civil circulation.

- When must the marking code payment be made?

For the duration of the experiment, the emission of marking codes is free. Upon completion of the experiment, from the date of the start of mandatory digital marking, the debiting of funds will occur until the submission of information about the introduction of goods into civil circulation.

- When must the marking code payment be made?

For the duration of the experiment, the emission of marking codes is free. Upon completion of the experiment, from the date of the start of mandatory digital marking, the debiting of funds will occur until the submission of information about the introduction of goods into civil circulation.

- Do I need to pay for re-emission of the marking code if it has been damage damaged?

The costs of a market member for losses from the write-off of goods/rejects are their own risk, regardless of whether their goods have been marked or not. This risk is not related to the service of providing marking codes by the Operator. Recognition of the marking code is retained if up to 30% of its area is damaged. Greater damage may indicate damage to the product packaging, rendering it non-compliant with the health and safety regulations. Since physical printing and application of the marking code are not included in the services provided by the Operator, incorrect application or damage to the code cannot be attributed to the risks of the Operator.

- Do I need to pay for re-emission of the marking code if it has been damage damaged?

The costs of a market member for losses from the write-off of goods/rejects are their own risk, regardless of whether their goods have been marked or not. This risk is not related to the service of providing marking codes by the Operator. Recognition of the marking code is retained if up to 30% of its area is damaged. Greater damage may indicate damage to the product packaging, rendering it non-compliant with the health and safety regulations. Since physical printing and application of the marking code are not included in the services provided by the Operator, incorrect application or damage to the code cannot be attributed to the risks of the Operator.

- Do I need to pay for re-emission of the marking code if it has been damage damaged?

The costs of a market member for losses from the write-off of goods/rejects are their own risk, regardless of whether their goods have been marked or not. This risk is not related to the service of providing marking codes by the Operator. Recognition of the marking code is retained if up to 30% of its area is damaged. Greater damage may indicate damage to the product packaging, rendering it non-compliant with the health and safety regulations. Since physical printing and application of the marking code are not included in the services provided by the Operator, incorrect application or damage to the code cannot be attributed to the risks of the Operator.

- What are the stages of digital marking implementation?

The track & trace system implementation project comprises several stages:

1. Preparatory stage: searching for optimal technologies for the application of marking codes, setting up the track & trace system, outreaching to industry enterprises to inform them of the goals and objectives of the implementation of the system to the greatest possible extent;

2. Experiment: testing the marking technologies in real life and at real enterprises, testing and adjusting the track & trace system, informing the industry about the results of the Experiment, and preparing for high-volume deployment;

3. High-volume deployment: all manufacturing enterprises, distribution networks, and retail chains implement the track & trace technology.

- What are the stages of digital marking implementation?

The track & trace system implementation project comprises several stages:

1. Preparatory stage: searching for optimal technologies for the application of marking codes, setting up the track & trace system, outreaching to industry enterprises to inform them of the goals and objectives of the implementation of the system to the greatest possible extent;

2. Experiment: testing the marking technologies in real life and at real enterprises, testing and adjusting the track & trace system, informing the industry about the results of the Experiment, and preparing for high-volume deployment;

3. High-volume deployment: all manufacturing enterprises, distribution networks, and retail chains implement the track & trace technology.

- What are the stages of digital marking implementation?

The track & trace system implementation project comprises several stages:

1. Preparatory stage: searching for optimal technologies for the application of marking codes, setting up the track & trace system, outreaching to industry enterprises to inform them of the goals and objectives of the implementation of the system to the greatest possible extent;

2. Experiment: testing the marking technologies in real life and at real enterprises, testing and adjusting the track & trace system, informing the industry about the results of the Experiment, and preparing for high-volume deployment;

3. High-volume deployment: all manufacturing enterprises, distribution networks, and retail chains implement the track & trace technology.

- What are the stages of the experiment? When is the experiment considered successful within a company?

The purpose of the experiment is to successfully test the entire flow of marked goods from manufacturing sites or import to disposal at checkouts.

The experiment consists of the following key steps:

1) Ordering a code from the track & and trace system and applying it on the finished product;

2) Transfer of information on the successful application of codes to the track & trace system;

3) Aggregation of products in shipping packages and aggregation of inventory item codes in the aggregation code;

4) Introduction of marked products into circulation and the generation of reports;

5) Flow of goods along the commodity distribution chain according to the electronic Universal Transfer Document (eUTD) with the transfer of codes between legal entities;

6) Withdrawal from the circulation of goods through checkouts or eUTD, without the right of resale.

- What are the stages of the experiment? When is the experiment considered successful within a company?

The purpose of the experiment is to successfully test the entire flow of marked goods from manufacturing sites or import to disposal at checkouts.

The experiment consists of the following key steps:

1) Ordering a code from the track & and trace system and applying it on the finished product;

2) Transfer of information on the successful application of codes to the track & trace system;

3) Aggregation of products in shipping packages and aggregation of inventory item codes in the aggregation code;

4) Introduction of marked products into circulation and the generation of reports;

5) Flow of goods along the commodity distribution chain according to the electronic Universal Transfer Document (eUTD) with the transfer of codes between legal entities;

6) Withdrawal from the circulation of goods through checkouts or eUTD, without the right of resale.

- What are the stages of the experiment? When is the experiment considered successful within a company?

The purpose of the experiment is to successfully test the entire flow of marked goods from manufacturing sites or import to disposal at checkouts.

The experiment consists of the following key steps:

1) Ordering a code from the track & and trace system and applying it on the finished product;

2) Transfer of information on the successful application of codes to the track & trace system;

3) Aggregation of products in shipping packages and aggregation of inventory item codes in the aggregation code;

4) Introduction of marked products into circulation and the generation of reports;

5) Flow of goods along the commodity distribution chain according to the electronic Universal Transfer Document (eUTD) with the transfer of codes between legal entities;

6) Withdrawal from the circulation of goods through checkouts or eUTD, without the right of resale.

- How do the participants benefit from the experiment?

— Testing the digital marking technology with consideration for the specifics of a particular manufacturing site. Outputs: a report on the possibility of applying marking to the products of a particular manufacturer; recommended equipment specifications with an eye on the particular characteristics of the manufacturing site; an understanding of the impact of the introduction of digital marking on the manufacturer’s or importer’s production cycle (changes in the packaging process, aggregation of products into shipping packages and subsequent product distribution); an understanding of the required changes in the business processes and technologies of the wholesale component and retail; the opportunity to evaluate the cost of the subsequent full-scale roll-out of the track & trace system at an early stage;

— Analysis of business processes altered by the introduction of marking. Outputs: early assessment of the volume of required changes in the business processes of manufacturing, logistics, sales and affiliate network (if applicable) and the opportunity to prepare for the changes in good time;

— An open discussion with the experiment’s participants on the mandatory rules for marking and circulation and the possibility to influence the shaping of the rules, even at the federal executive level. Outputs: mandatory rules for marking that take comments from manufacturing sites into account.

- How do the participants benefit from the experiment?

— Testing the digital marking technology with consideration for the specifics of a particular manufacturing site. Outputs: a report on the possibility of applying marking to the products of a particular manufacturer; recommended equipment specifications with an eye on the particular characteristics of the manufacturing site; an understanding of the impact of the introduction of digital marking on the manufacturer’s or importer’s production cycle (changes in the packaging process, aggregation of products into shipping packages and subsequent product distribution); an understanding of the required changes in the business processes and technologies of the wholesale component and retail; the opportunity to evaluate the cost of the subsequent full-scale roll-out of the track & trace system at an early stage;

— Analysis of business processes altered by the introduction of marking. Outputs: early assessment of the volume of required changes in the business processes of manufacturing, logistics, sales and affiliate network (if applicable) and the opportunity to prepare for the changes in good time;

— An open discussion with the experiment’s participants on the mandatory rules for marking and circulation and the possibility to influence the shaping of the rules, even at the federal executive level. Outputs: mandatory rules for marking that take comments from manufacturing sites into account.

- How do the participants benefit from the experiment?

— Testing the digital marking technology with consideration for the specifics of a particular manufacturing site. Outputs: a report on the possibility of applying marking to the products of a particular manufacturer; recommended equipment specifications with an eye on the particular characteristics of the manufacturing site; an understanding of the impact of the introduction of digital marking on the manufacturer’s or importer’s production cycle (changes in the packaging process, aggregation of products into shipping packages and subsequent product distribution); an understanding of the required changes in the business processes and technologies of the wholesale component and retail; the opportunity to evaluate the cost of the subsequent full-scale roll-out of the track & trace system at an early stage;

— Analysis of business processes altered by the introduction of marking. Outputs: early assessment of the volume of required changes in the business processes of manufacturing, logistics, sales and affiliate network (if applicable) and the opportunity to prepare for the changes in good time;

— An open discussion with the experiment’s participants on the mandatory rules for marking and circulation and the possibility to influence the shaping of the rules, even at the federal executive level. Outputs: mandatory rules for marking that take comments from manufacturing sites into account.

- What company sizes are eligible to take part in the experiment? Is there a minimum number of SKUs required to join the pilot project?

There are no limits on company size or the number of SKUs required to join the experiment; however, it is advisable to use multiple different package form factors and production lines.

- What company sizes are eligible to take part in the experiment? Is there a minimum number of SKUs required to join the pilot project?

There are no limits on company size or the number of SKUs required to join the experiment; however, it is advisable to use multiple different package form factors and production lines.

- What company sizes are eligible to take part in the experiment? Is there a minimum number of SKUs required to join the pilot project?

There are no limits on company size or the number of SKUs required to join the experiment; however, it is advisable to use multiple different package form factors and production lines.